In the realm of technological innovation, 3D printing stands as a shining example of progress that has taken industries by storm. From revolutionizing manufacturing processes to reshaping healthcare, the advancements in 3D printing technology have opened doors to new possibilities.

This article delves into the world of 3D printing, additive manufacturing, and rapid prototyping, exploring how these techniques are transforming various sectors. By understanding techniques like Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and more, we can grasp the true extent of their applications.

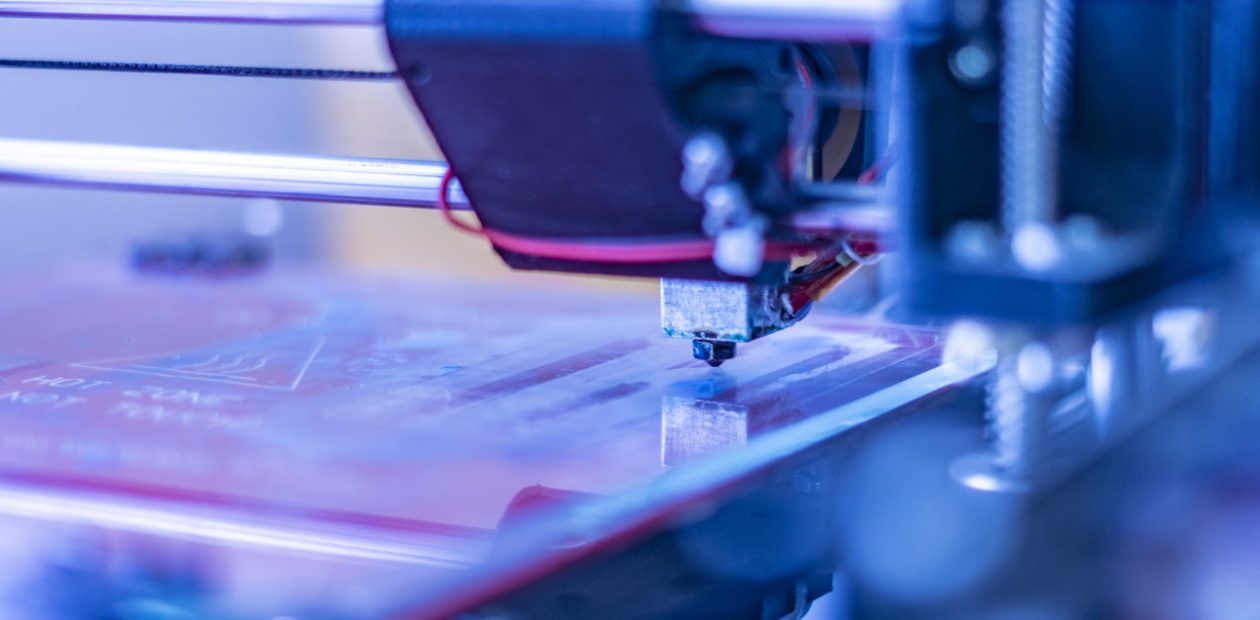

3D Printing: A Game-Changing Technology

At its core, 3D printing, also known as additive manufacturing, is a revolutionary technique that constructs objects layer by layer, ultimately bringing digital designs to life. This process has disrupted traditional manufacturing methods, as it eliminates the need for molds, tools, and extensive material wastage. The term “3D printing” itself is an umbrella that covers various techniques, each with its unique approach and applications.

Additive Manufacturing: Crafting the Future

Additive manufacturing, often used interchangeably with 3D printing, entails the creation of three-dimensional objects by adding material layer by layer. Unlike traditional subtractive methods, where material is removed from a block to form a shape, additive manufacturing builds from scratch, optimizing material usage and design flexibility.

Rapid Prototyping: Accelerating Innovation

Rapid prototyping is one of the standout applications of 3D printing. It allows designers and engineers to swiftly create prototypes of products, enabling quick iterations and improvements. This speeds up the development cycle and ensures that the final product aligns closely with the intended design.

Layer-by-Layer Printing: Building Block by Block

The foundation of 3D printing lies in its layer-by-layer approach. This technique enables the creation of intricate and complex geometries that would be challenging or impossible to achieve through traditional methods. By stacking layers upon layers, the technology achieves precision and detail that were previously unattainable.

Fused Deposition Modeling (FDM): Bridging Ideas and Reality

Among the various techniques under the 3D printing umbrella, Fused Deposition Modeling (FDM) stands as a prominent player. FDM involves extruding thermoplastic material layer by layer, which then fuses together as it cools down. This technique finds extensive use in various industries, ranging from aerospace to consumer goods.

With FDM, it’s possible to create functional prototypes, concept models, and even end-use parts. Its versatility lies in its ability to work with a wide range of materials, making it an attractive option for engineers and designers seeking rapid and cost-effective solutions.

Stereolithography (SLA): Illuminating Precision

Stereolithography, commonly referred to as SLA operates on a different principle than FDM. It uses photopolymerization, wherein a liquid resin is solidified layer by layer using ultraviolet light. SLA is renowned for its unparalleled precision and ability to produce intricate details.

SLA has found its niche in industries demanding high accuracy, such as jewelry design, dental prosthetics, and medical devices. Its precision and surface finish make it an excellent choice for applications where quality is paramount.

Selective Laser Sintering (SLS): Fusing Powders into Reality

Selective Laser Sintering (SLS) takes a unique approach by using powdered material as the base. A high-powered laser selectively fuses the powder particles, layer by layer, forming a solid structure. This technique is celebrated for its versatility in materials, which range from plastics to metals.

Industries like automotive, aerospace, and healthcare benefit from SLS due to its ability to create functional prototypes and end-use parts in a variety of materials. The absence of support structures also allows for complex geometries that would be challenging with traditional methods.

Digital Light Processing (DLP): Illuminating Possibilities

Digital Light Processing (DLP) is another noteworthy 3D printing technique that employs photopolymerization. However, unlike SLA, DLP uses a digital light projector to flash an entire layer at once, expediting the printing process. This technique strikes a balance between speed and precision. DLP finds its applications in dentistry, jewelry casting, and consumer electronics. Its speed and accuracy make it a valuable asset when time is of the essence without compromising on quality.

Material Extrusion: Layering for Strength

Material extrusion, synonymous with Fused Filament Fabrication (FFF), is a technique that feeds thermoplastic filament through a heated nozzle. Material extrusion is popular due to its accessibility and affordability. The applications of material extrusion are vast, spanning from hobbyists creating intricate models to engineers prototyping mechanical parts. Its simplicity and versatility have contributed to its widespread adoption.

Applications in Manufacturing and Healthcare

Manufacturing Revolution: On-Demand Production

3D printing has disrupted traditional manufacturing methods by introducing on-demand production. Companies can manufacture parts, tools, and products as needed, eliminating the need for massive inventories and costly tooling. This flexibility has transformed supply chains, making them more agile and cost-efficient.

Personalized Medical Solutions: A New Era in Healthcare

In healthcare, 3D printing has catalyzed a new era of personalized solutions. Surgeons can now plan complex procedures with detailed 3D-printed anatomical models, enhancing accuracy and reducing surgical risks. Moreover, custom implants and prosthetics can be tailored to each patient’s unique anatomy, significantly improving patient outcomes.

Sustainable Practices: Minimizing Waste

The layer-by-layer approach of 3D printing has environmental implications as well. Traditional manufacturing often generates substantial waste through subtractive processes. In contrast, 3D printing minimizes material wastage, contributing to more sustainable practices and reduced carbon footprints.

Conclusion

3D printing has emerged as a transformative force, reshaping industries and pushing the boundaries of what’s possible. From the intricate precision of SLA to the versatility of FDM, these techniques have revolutionized manufacturing and healthcare. As the technology continues to evolve, it promises to unlock new avenues of creativity, sustainability, and efficiency. Embracing the advancements in 3D printing technology is not just a leap into the future; it’s a step towards shaping a more innovative and personalized world.

FAQs

Is 3D printing only used for prototyping?

No, 3D printing has evolved beyond prototyping. It is now widely used for creating functional end-use parts, custom medical implants, jewelry, consumer goods, and even architectural models.

Can 3D-printed objects be made with different materials?

Yes, various 3D printing techniques support a wide range of materials, including plastics, metals, ceramics, and even food-grade materials.

Is 3D printing suitable for mass production?

While 3D printing excels in producing low to medium volumes of highly customized parts, traditional manufacturing methods are often more efficient for mass production due to factors like speed and cost per unit.

How accurate is 3D printing?

The accuracy of 3D printing varies based on the technique used and the machine’s capabilities.

High-precision techniques like SLA and SLS can achieve accuracy within fractions of a millimeter.

What is the future of 3D printing?

The future of 3D printing holds immense potential. As technology advances, we can expect even faster printing speeds, greater material diversity, and more innovative applications across industries.

Is 3D printing accessible for small businesses?

Yes, with the advent of desktop 3D printers, small businesses, and even individuals can harness the power of 3D printing for various applications, from creating prototypes to producing small batches of products.